- Select language

English/product/waterproof-insulation-composite-tape/

English/product/waterproof-insulation-composite-tape/ العربية/ar/product/waterproof-insulation-composite-tape/

العربية/ar/product/waterproof-insulation-composite-tape/ Français/fr/product/waterproof-insulation-composite-tape/

Français/fr/product/waterproof-insulation-composite-tape/ Deutsch/de/product/waterproof-insulation-composite-tape/

Deutsch/de/product/waterproof-insulation-composite-tape/ Italiano/it/product/waterproof-insulation-composite-tape/

Italiano/it/product/waterproof-insulation-composite-tape/ Português/pt/product/waterproof-insulation-composite-tape/

Português/pt/product/waterproof-insulation-composite-tape/ Русский/ru/product/waterproof-insulation-composite-tape/

Русский/ru/product/waterproof-insulation-composite-tape/ Español/es/product/waterproof-insulation-composite-tape/

Español/es/product/waterproof-insulation-composite-tape/

Waterproof and insulating protection for various equipment and application conditions in power and communication, waterproof and sealing protection for cable joints and terminals, especially waterproof and insulating sealing for cold shrinkage intermediate joints of power cables.

Cable outer sheath protection and repair, waterproof insulation treatment of overhead insulated wire joints; waterproof insulation sealing of optical cables, communication cable connections and joints such as communication base stations, antennas, feeders, etc.; smoothing treatment and waterproof sealing of busbar contacts.

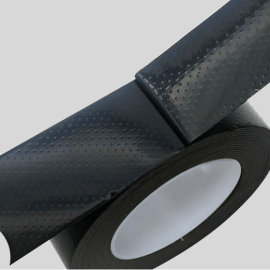

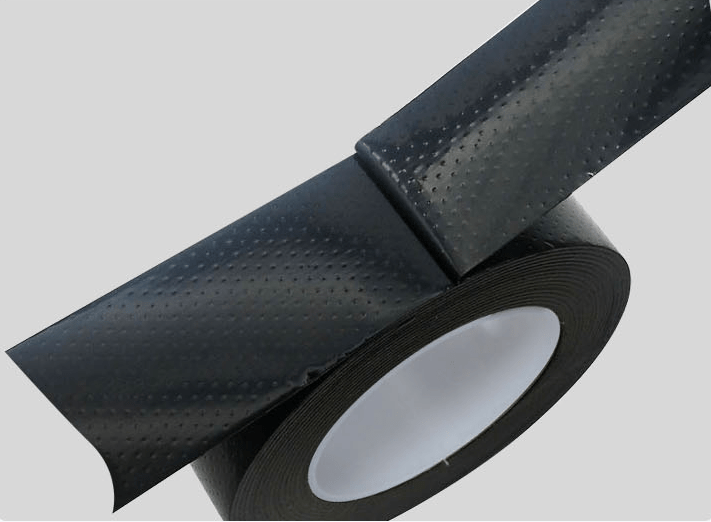

BLJ-80, 1.65*50*3000mm, polymer resistance material.

Waterproof insulating composite tape is made of polymer barrier base material and adhesive material. It has excellent electrical insulation, adhesion, waterproof and airtightness, acid, alkali and salt resistance, etc. It is chemically corrosive, resistant to UV aging and ozone, and resistant to high and low temperatures. The normal operating temperature is -40℃~90℃, and the emergency overload temperature is 130℃.

It is preferably made of high-molecular resistance material, with good toughness, not easy to age and resistant to acid and alkali corrosion.

Waterproof sealing protection of power cable joints and terminals, especially waterproof insulation sealing of cold shrinkage intermediate joints of power cables. Waterproof insulation sealing of submersible motor cable joints. Chemical industry, anti-corrosion sealing protection of electromechanical pipelines in mines, railways, tunnels and subways. Waterproofing of wires and cables, optical cables and communication cables. Anti-corrosion insulation protection.

application: